OCT 12, 2019 (Investing Alerts) — For any industry to succeed, it needs optimal supply chain management to follow through with business processes. From planning stages, all the way to delivering the final product, supply chain management is crucial and should not be taken lightly.

As an ever-growing part of the industry, professionals interested in learning how to manage supply chains will need to stay up-to-date with the latest developments out there. What is it that they’re doing differently?

According to Resilinc Annual EventWatch Report, global supply chain risk events increased 36% in 2018. Any single risk event can have a heavy impact on business, regardless of whether they operate locally or on a global scale.

Supply Chain Risk Management Consortium argues that companies should analyze, assess, and address risk and disruptions as a collective industry instead of separate entities.

Supply chain risk management falls into the categories of strategic, tactical, and operational planning. Most events are outside of the company’s control, but efforts can still be made to prevent and manage it. Companies are sharing their experience and joining together to set industry-standards for events such as:

- Natural disasters

- Fires or explosions

- Cyberthreats

- Transportation disruptions

- Demographic shifts

- Government intervention

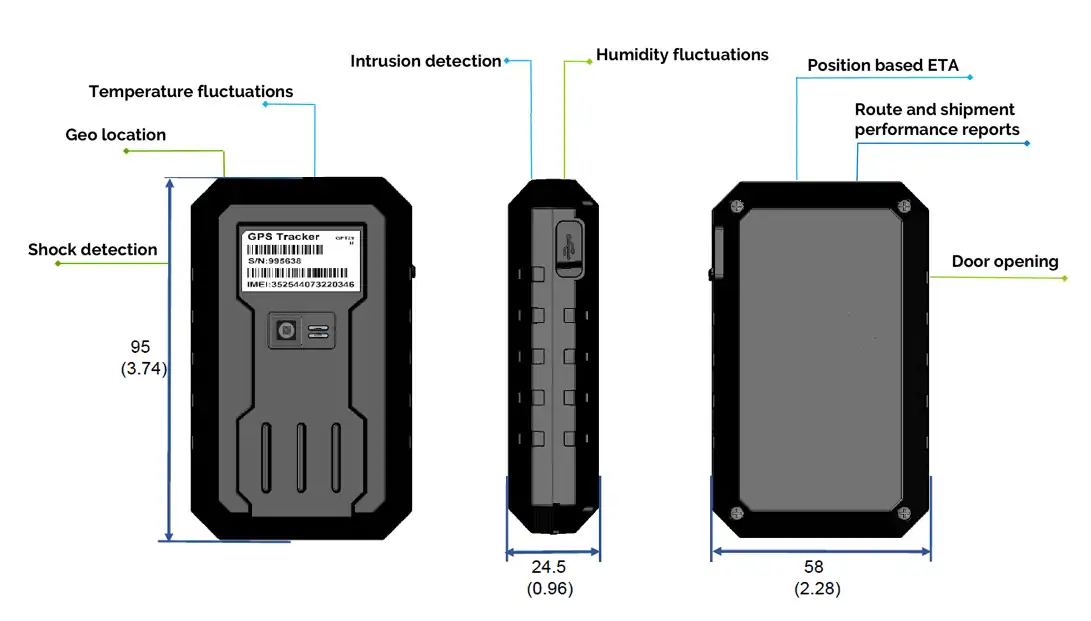

SCM companies are beginning to implement more monitoring with the use of newer supply chain trackers. In companies that handle food and pharmaceutical products, the need for supply chain tracking devices and automated data collection is increased due to quality control. Through improved track and trace solutions, companies can prevent food recalls from occurring in the future.

The use of track and trace technologies such as supply chain IoT devices provides transparency for both fleet management and consumer levels. It provides more information on whereabouts on inventory and better security for drivers and their vehicles. With built-in tracking systems, companies experience benefits around the whole operation.

As the heart of a company’s operations, managers need access to real-time data to make the best decisions. Leading companies are already beginning to look into alternatives for more automated service, thanks to blockchain technology.

Where a lack of transparency or accountability could make or break a supply chain, blockchain is a global system that ensures a highly monitored flow of goods and services between businesses and beyond. It allows crucial data to be updated in real-time for all parties involved, and it eliminates any conflict with internal records.

With the advancement of new strategies and technologies, supply chain managers face new challenges to keep their company above water. It’s no longer only about profits and productivity – it’s about keeping the company’s name away from the headlines and lawsuits while meeting the new global market standards.