NB-IoT Applications in Modern Logistics Asset Tracking

NB-IoT is a cellular IoT technology that is reshaping how logistics and supply-chain professionals track assets in real time. From cold-chain pharmaceutical shipments to global container fleets, NB-IoT brings new levels of visibility and efficiency to modern logistics. Traditionally, tracking assets in transit relied on manual logs—or at best scanning at checkpoints—leaving large blind spots in between. NB-IoT changes this paradigm by allowing continuous, granular tracking throughout a shipment’s journey.

The stakes are high: the cold-chain logistics market alone is forecast to expand from US $342.8 billion in 2023 to more than US $1.24 trillion by 2033, a staggering ~14 % CAGR [^1]. This expansion underscores the growing demand for advanced tracking and monitoring technologies to ensure goods arrive in optimal condition. In response, IoT connectivity solutions like NB-IoT are gaining traction for their ability to deliver ubiquitous, energy-efficient asset tracking at scale.

Modern logistics operations integrate digital tools and IoT sensors to monitor assets throughout warehouses and distribution centers. Today’s supply chains generate vast amounts of data, and stakeholders demand real-time visibility into shipments’ conditions and locations. NB-IoT has emerged as a key enabler by connecting a new generation of asset-tracking devices across global logistics networks. In the following sections we delve into NB-IoT’s benefits and concrete applications—from temperature-controlled pharma shipping to fleet and cargo tracking—illustrating how this technology is shaping the future of supply-chain management.

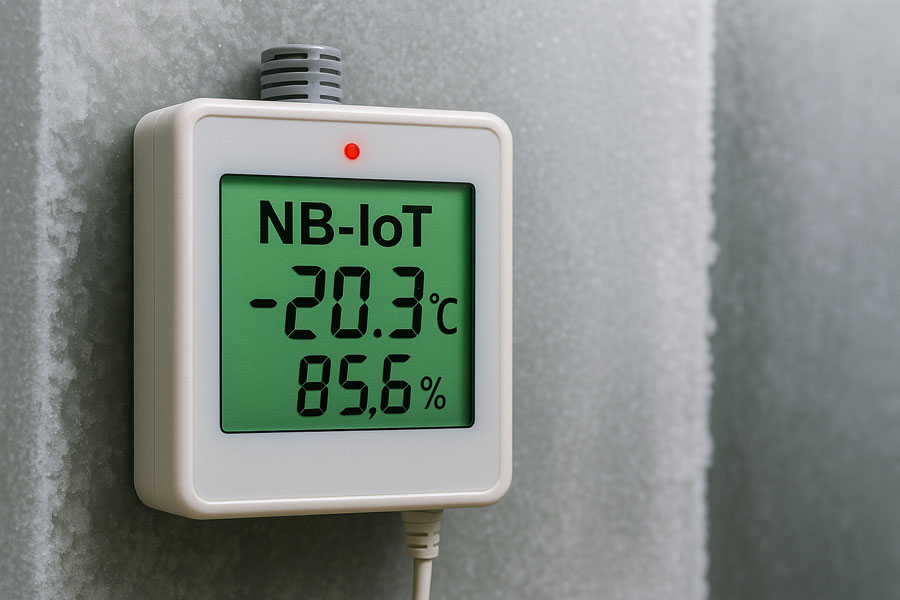

NB-IoT data logger delivers real-time temperature and humidity readings in frozen cold-chain environments

Why NB-IoT for Logistics Asset Tracking

NB-IoT is a Low-Power Wide-Area Network (LPWAN) protocol standardized by 3GPP. It operates in licensed cellular spectrum but uses very narrow bandwidth, allowing devices to send short bursts of data with minimal energy. For logistics applications this translates to several key advantages:

-

Extended battery life – many trackers operate for years on a single battery [^2], depending on report frequency (devices remain in deep-sleep mode between transmissions). A long-battery-life GPS asset tracker equipped with NB-IoT can accompany an international shipment or container on multi-month voyages without needing a recharge.

-

Deep coverage & connectivity – NB-IoT signals penetrate challenging locations such as warehouses, shipping containers, underground storage, or remote rural areas where traditional cellular often struggles [^2].

-

Massive scalability – networks can support tens of thousands of devices per cell site thanks to NB-IoT’s narrow-band operation [^2].

-

Cost-effectiveness – NB-IoT leverages existing cellular infrastructure and inexpensive chipsets; data plans are typically low-cost because the payloads are small [^2][^3].

-

Reliability & security – operating in licensed spectrum with carrier-grade networks, NB-IoT inherits 3GPP encryption and authentication mechanisms, which is crucial for industries that require data integrity and compliance [^2].

By 2023 there were 140+ commercial NB-IoT networks across 64 countries [^4], giving the technology a truly global footprint to support international supply chains. Many asset trackers are multi-mode (supporting LTE-M or GSM fallback) to ensure connectivity even if NB-IoT coverage is temporarily unavailable.

In essence, NB-IoT fills the gap between short-range RFID/Bluetooth trackers and high-power cellular devices by offering a sweet spot of long range, low power, and low cost. Compared with legacy approaches (manual records or sparse GPS pings), NB-IoT feeds continuous location and sensor data into cloud platforms—granting logistics managers a live, granular view of assets that was difficult to achieve before.

Cold-Chain Monitoring with NB-IoT: Preserving Perishables & Pharma

Futuristic dashboard visualizing NB-IoT temperature data and alerts for cold-chain logistics.

Roughly one-third of global food production is lost to spoilage each year, much of it due to breaks in the cold chain [^5]. The pharmaceutical industry likewise ships growing volumes of temperature-sensitive biologics and vaccines. Failure to maintain proper conditions can ruin products, incur regulatory penalties, and even endanger lives. During the COVID-19 vaccine rollout, for instance, every carton carried a digital logger to verify temperature compliance throughout transit [^6].

NB-IoT excels here. By equipping refrigerated trucks, containers, and packages with wireless temperature sensors connected via NB-IoT, logistics providers can continuously monitor conditions in transit. A tracker might log cargo temperature every few minutes and transmit summaries (or immediate alerts) if thresholds are breached. Regulations such as the FDA’s FSMA and the EU’s GDP explicitly mandate rigorous temperature tracking and record keeping [^7]—tasks NB-IoT automates far more reliably than periodic manual checks.

A number of solution providers now offer dedicated NB-IoT devices tailored for cold-chain monitoring. Eelinktech, for example, builds multi-sensor trackers that record temperature, humidity, and location while running on battery for years [^8]. These rugged units operate even in extreme sub-zero environments, making them ideal for frozen or refrigerated shipments.

Learn more about Eelink cold-chain tracking solutions

By reducing spoilage and quality incidents, NB-IoT solutions also deliver sustainability benefits—curbing waste and lowering the carbon footprint associated with perished goods.

Tracking Cargo, Containers & Equipment with NB-IoT

Beyond perishables, NB-IoT-powered trackers are used to monitor shipping containers, trailers, pallets, and returnable transport items. Compact NB-IoT GPS units can report a container’s location and status even mid-ocean (assuming coverage or satellite relay). If a container deviates from its planned route or is opened unexpectedly, alerts flag potential theft or tampering. Cargo-theft losses in 2024 exceeded US $455 million across the U.S. and Canada [^8].

Industrial equipment and reusable assets benefit too: low-cost tags help locate idle items, optimise utilisation, and prevent loss. Global carriers are already embracing NB-IoT. Maersk, for instance, is rolling out a unified IoT network across its 450-ship fleet to support NB-IoT and LTE-M devices—delivering seamless container visibility at sea, in port, and on land [^9].

From Data to Decisions: Supply-Chain Visibility & Analytics

The true power of NB-IoT emerges when telemetry feeds into broader logistics platforms. Each tracker’s pings (location, temperature, shock) stream into cloud dashboards that update a shipment’s status in real time. Stakeholders can pinpoint delays, reroute proactively, and verify chain of custody at a glance.

Historical datasets unlock predictive analytics: algorithms detect patterns (e.g., a refrigeration unit’s efficiency drift) and flag potential failures. In one industry example, anomaly detection helped companies avert up to 65 % of potential disruptions by acting on early warning signs [^10].

Conclusion: Future-Proofing Logistics with NB-IoT

From ensuring vaccines remain potent to locating containers across oceans, NB-IoT is becoming a cornerstone of modern logistics. Its unique blend of low power, wide coverage, and low cost connects millions of assets that were previously invisible. As customer expectations for transparency rise, NB-IoT adoption will only accelerate—augmented by forthcoming satellite IoT links and 5G RedCap devices to eliminate the last black spots.

Forward-thinking firms like Eelink are already harnessing NB-IoT trackers and data analytics to build smarter, more resilient supply chains—delivering greater reliability, sustainability, and efficiency. In short, NB-IoT is shifting asset tracking from a reactive afterthought to a proactive, data-driven strategy that adds real value every day.

References

| # | Source | Note |

|---|---|---|

| 1 | IoT For All – “Global Cold-Chain Market Forecast 2023–2033.” | Market-size & CAGR figures |

| 2 | Matellio – “NB-IoT vs LTE-M: Key Differences & Use-Cases,” 2024. | Battery life, coverage, scalability |

| 3 | Matellio – “Cost Benefits of NB-IoT for Asset Tracking,” 2024. | Cost-effectiveness, security |

| 4 | Total Telecom – “NB-IoT Networks Exceed 140 Worldwide,” Nov 2023. | Global network count |

| 5 | Eelinktech White Paper – “Food Waste and Supply-Chain Visibility,” 2024. | One-third food-loss statistic |

| 6 | Food Logistics – “Lessons from COVID-19 Vaccine Cold Chain,” 2023. | Vaccine logger example |

| 7 | Food Logistics – “FSMA & GDP Compliance in IoT Cold Chains,” 2024. | Regulatory requirements |

| 8 | Burns & Wilcox – “Cargo Theft Report 2024.” | 2024 theft losses |

| 9 | Maersk Press Release – “Unified IoT Network Across Fleet,” 2024. | Maersk NB-IoT deployment |

| 10 | Eelinktech Field Data – DB01 Predictive-Maintenance Pilot, 2024. | 65 % disruption reduction |

© 2025 Eelink Communication Technology – Content authored & fact-checked by Apple Ko.