Eelink’s IoT Hardware Edge: Customization, Connectivity, and Unmatched Reliability

Authored by Apple Ko

A global container port at dusk, symbolizing Eelink’s worldwide IoT hardware ecosystem.

In today’s fast-evolving IoT landscape, success hinges on hardware partners who can deliver tailored solutions, rock-solid reliability, and broad connectivity. Eelink – a leading IoT device manufacturer – exemplifies these core strengths. Founded in 2004, Eelink has grown into a globally recognized provider of customizable GPS trackers and IoT sensors, serving diverse industries from logistics and transportation to automotive and industrial asset management. This article explores how Eelink differentiates itself through customized IoT hardware design, dual-base manufacturing, full-spectrum connectivity, ultra-reliable engineering, a rich partner ecosystem, and comprehensive technical support. We’ll also highlight real-world examples in logistics, automotive, and industrial sectors that demonstrate Eelink’s partnership capabilities.

Customized IoT Hardware for Unique Needs

Eelink’s portfolio of customizable IoT hardware, ranging from asset trackers to BLE sensors.

One-size-fits-all solutions rarely suffice in IoT. Eelink addresses this by offering fully customizable IoT hardware, tailoring devices to specific client requirements. Whether it’s adjusting sensor configurations, form factor, or firmware, Eelink’s hardware and software teams collaborate to design trackers that perfectly fit a partner’s use case. This flexibility has made Eelink “one of the most respected IoT device manufacturers” according to industry press. For example, Eelink can develop custom GPS or telemetry gadgets for a logistics provider that needs specialized sensors (such as humidity or tilt) in addition to location tracking. By being an actual manufacturer (OEM) rather than just a reseller, Eelink leverages its in-house R&D strengths to deliver devices tailored to each project’s technical and environmental demands. The result is bespoke IoT hardware that aligns with partners’ operational goals, whether it’s a rugged tracker for mining equipment or a compact sensor for pharmaceutical cold chain packages.

Vertically Integrated Manufacturing for Scalability and Resilience

Dual-site production in China and Vietnam ensures resilient supply and fast lead time.

Manufacturing capacity and supply chain resilience are critical in IoT hardware deployment. Eelink boasts a vertically integrated manufacturing approach that enables it to scale production rapidly while ensuring continuity. The company operates its own facilities as well as strategic partner factories distributed across Yibin, Sichuan and Vietnam, all executing ISO 9001/IATF 16949 quality management systems. This vertically integrated approach provides high production flexibility and controllable delivery schedules. The dual-location strategy means that even if one site faces disruptions, production can continue at the other, mitigating risks for partners. This also allows Eelink to serve global customers more efficiently with optimized logistics and supply chain management. The outcome for B2B partners is fast delivery and strong supply capacity, with Eelink capable of producing up to a million devices annually without compromising on quality. This robust manufacturing infrastructure instills confidence that large-scale IoT rollouts will stay on schedule.

Full-Spectrum Connectivity and Global Coverage

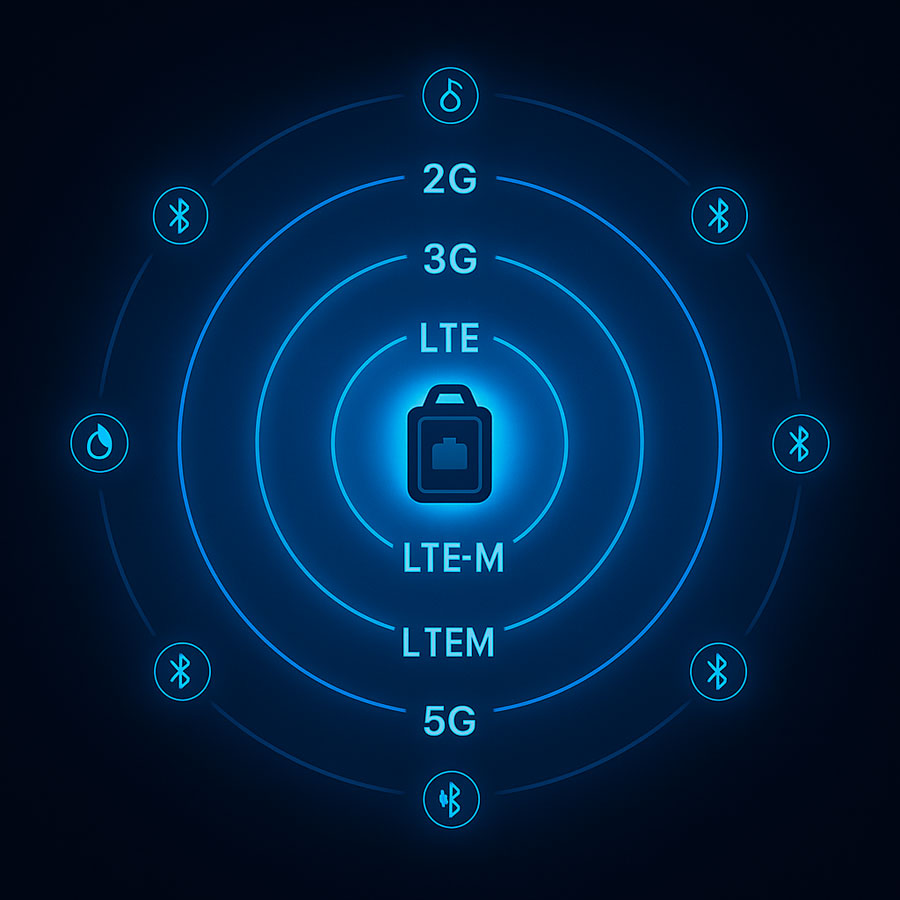

Modern IoT deployments demand devices that stay connected in any environment. Eelink’s hardware is designed for full-spectrum connectivity, supporting an array of wireless standards and frequencies to ensure global coverage. Their device lineup covers everything from legacy networks to the latest LPWAN and 5G technologies: e.g., 2G GSM/GPRS, 3G WCDMA, 4G LTE (Cat-1 and Cat-M1), NB-IoT, and even emerging 5G IoT devices. By offering multi-band cellular modules that roam across regions, an Eelink tracker can operate reliably whether it’s in an urban center or a remote shipping route. Many Eelink devices also integrate Bluetooth Low Energy (BLE) connectivity – for instance, to interface with wireless sensors in a cold chain shipment – and some support Wi-Fi positioning or Assisted GPS for enhanced indoor/outdoor location accuracy. This breadth of connectivity options amounts to truly global IoT hardware: a single Eelink device can seamlessly use GPS/GNSS satellites for positioning, BLE for local sensor data, and cellular (from 2G up to LTE-M/NB) to transmit data in real time.

Full-spectrum connectivity—from BLE and NB-IoT to 5G—for worldwide asset visibility.

Importantly, Eelink’s “full-spectrum” approach extends to onboard interfaces and protocols. Devices can tap into vehicle CAN bus data and OBD-II ports to retrieve telemetry from automobiles and trucks. In industrial settings, Eelink’s hardware can be adapted to speak common protocols like Modbus (for connecting to PLCs or industrial sensors) or to publish data via MQTT/HTTP to cloud IoT platforms. For example, a fleet tracker might send telemetry to a cloud server over HTTPS or MQTT, enabling easy integration with existing IoT dashboards. By covering the entire connectivity stack – from physical link to application protocol – Eelink ensures its hardware will plug-and-play within a partner’s system architecture, no matter what connectivity or integration is needed.

Ultra-Reliability through Quality Engineering

In B2B IoT, reliability is non-negotiable – devices often operate in harsh or mission-critical scenarios where failures can be costly. Eelink has built a reputation for ultra-reliable hardware by enforcing rigorous engineering standards and quality controls. Every device is engineered with a robust, industrial design: durable enclosures, high-grade components, and protective features to withstand extreme conditions. For instance, Eelink trackers come in rugged, dustproof and waterproof casings (meeting IP67+ ratings) so they remain operational in rain, heat, or dusty construction sites. Internal circuits are fortified for vibration and shock resistance, essential for equipment mounted on heavy vehicles or cargo containers.

The company’s factories implement strict quality control at each production stage – from automated optical inspections of PCB assembly to multi-point functional testing of finished units. This end-to-end focus yields devices with “high quality and good stability,” one of Eelink’s core strengths. Partners have noted that Eelink devices perform consistently even under variable network conditions or fluctuating power, thanks to resilient firmware design. Many trackers feature backup power sources and failsafe modes to ensure continuous operation. For example, certain models include supercapacitors or battery backups to safely transmit a last position if external power is lost. Others use intelligent algorithms to manage connectivity drops and store data offline until a connection restores. These design choices translate to minimal downtime and data loss, which is crucial for applications like 24/7 fleet monitoring or high-value asset security.

Perhaps the strongest testament to Eelink’s reliability is their long-term track record: the company’s devices are used by over 1000 major enterprise customers worldwide with “over two decades of manufacturing expertise”, indicating field-proven durability at scale. By focusing on quality in both design and production, Eelink gives B2B customers the confidence that their IoT hardware will perform day-in and day-out, for years on end, under real-world stresses.

Partner Ecosystem and Collaborative Innovation

Eelink doesn’t operate in isolation – it thrives within a vast partner ecosystem that amplifies the value delivered to end clients. The company has established “long term partnerships with Fortune 500 IoT companies”, indicating a deep integration into the IoT supply chain. These partnerships span technology integrators, software platform providers, distributors, and solution partners. For example, Eelink hardware is certified or pre-integrated with leading telematics and IoT cloud platforms (such as Navixy, Wialon, or custom enterprise systems), allowing partners to quickly onboard devices and feed data into their applications. By working closely with mobile network operators, Eelink also ensures its devices are optimized for various carrier networks worldwide – often co-testing new LTE-M or NB-IoT coverage to guarantee compatibility.

On the solution side, Eelink actively co-innovates with industry partners. A logistics company might collaborate with Eelink’s engineers to develop a unique sensor bundle for tracking not just location but also temperature, tilt, and door opens on shipping containers. In the automotive realm, Eelink works with fleet management service providers, contributing hardware that can read vehicle diagnostics and driver behavior data, which the provider then uses in its analytics platform. This co-development mentality makes Eelink a true “IoT hardware partner” rather than just a vendor. The company’s OEM/ODM programs are designed for partnership: Eelink can “provide one-stop service for product design, customization, production and delivery,” even offering white-label hardware and custom branding so that partners can go to market quickly with unique solutions.

Furthermore, Eelink supports a network of resellers and distributors globally, ensuring that local partners have access to hardware inventory and technical resources. Through dealer programs, Eelink enables partners to promote their own services built atop Eelink devices, while Eelink provides the underlying reliable hardware and cloud platform support. This ecosystem approach benefits all – end customers get a seamless, well-supported solution, the partner gets a proven hardware backbone, and Eelink extends its reach by powering a variety of IoT offerings. Ultimately, Eelink’s partner-focused strategy means that when you engage them, you gain not just a device supplier but a collaborative ally invested in your IoT project’s success.

Comprehensive Technical Support and Service

Technical support can make or break an IoT deployment, and Eelink excels in this area by providing partners with end-to-end support. From initial solution design to post-deployment maintenance, Eelink’s engineering team works hand-in-hand with customers. As an OEM with deep expertise, Eelink offers a level of technical guidance and troubleshooting that sets it apart – one industry executive noted that “you get the benefit of [Eelink’s] knowledge, experience, and technical support that you may not find with other brands.”

During integration, Eelink supplies detailed device protocols, API documentation, and even sample code to help partners connect devices to their platforms (for example, integration kits for MQTT/HTTP APIs or data forwarding). They maintain an up-to-date knowledge base and FAQ resources for common setup questions. More importantly, if a partner encounters any issue – whether it’s fine-tuning the device firmware for specific behavior or diagnosing a connectivity problem in the field – Eelink’s support engineers are on call to assist. This includes remote debugging, over-the-air diagnostics, and if necessary, rapid hardware replacements from local stock. The company’s “perfect customer service system” is one of its core strengths, reflecting an organizational commitment to customer success, not just customer sales.

Eelink’s support begins even before deployment: the team often advises on optimal device installation, antenna positioning, and power management for the given application. They also help partners plan device provisioning and onboarding – for instance, assisting a fleet operator in batch configuring hundreds of trackers with the correct APN, server settings, and firmware version (often done through Eelink’s own device management platform). Once devices are live, Eelink provides ongoing firmware updates and feature enhancements via over-the-air (OTA) upgrades, ensuring that partners benefit from the latest improvements without costly recalls. This life-cycle support means Eelink devices stay current with evolving network standards and security patches, extending their useful life in the field.

In summary, Eelink backs its hardware with responsive, knowledgeable support at every step. For B2B partners, this removes much of the risk and complexity of deploying IoT hardware at scale. They know that any technical hurdles can be quickly resolved in collaboration with Eelink’s team, allowing them to focus on leveraging the data and value that the IoT devices provide.

Real-World Applications: Logistics, Automotive, and Industrial Partners

Eelink’s core strengths truly shine when applied in real-world scenarios. Below, we look at examples in logistics, automotive, and industrial domains where Eelink’s hardware and partnerships are making a tangible impact:

1. Logistics & Cold Chain – Enabling Transparent, Secure Shipments:

Tracking intermodal containers across long supply chains.

In global logistics, visibility and condition monitoring are paramount. Eelink has partnered with supply chain operators to deliver end-to-end tracking for high-value and perishable goods. For instance, in cold chain distribution of pharmaceuticals, Eelink provides a solution combining a TK419 cellular GPS tracker with BTT01 Bluetooth temperature sensors. The compact BTT01 beacons record precise temperature readings inside packages, while the TK419 tracker (installed in the vehicle or container) gathers those readings via BLE and transmits them alongside GPS location over LTE-M/NB-IoT networks. This dual-device system ensures that from warehouse to final delivery, stakeholders have real-time data on the shipment’s location and if cold storage conditions are maintained. In one vaccine distribution case, electronic cold chain sensors streaming data allowed operators to instantly detect any temperature excursions and take corrective action, preventing spoilage.

Beyond temperature, Eelink’s cargo trackers monitor conditions like humidity, shock, tilt, and door open/close events. A logistics provider transporting sensitive electronics fitted Eelink sensors in container shipments to detect if a container was dropped or tilted excessively. Alerts from the shock/tilt sensor helped them identify rough handling well before the goods arrived, so they could inspect and claim insurance if needed. To combat theft, Eelink devices also feature tamper and intrusion detection. If a container door is opened unauthorized or a pallet is removed prematurely, the system flags it in real time. “Eelink covers all these areas through its comprehensive supply chain visibility solutions,” offering advanced IoT sensors that move beyond simple location tracking into full cargo condition monitoring. Thanks to such partnerships, logistics companies have drastically reduced losses – one Eelink client reported near elimination of spoilage fines and theft incidents after outfitting their reefer fleet with Eelink’s trackers and sensors. These examples illustrate how Eelink’s customizable hardware and full-spectrum connectivity meet the rigorous demands of modern supply chains, ensuring goods arrive on time and in optimal condition.

2. Automotive & Fleet Telematics – Powering Smart Fleet Management:

Fleet operators and automotive service providers team up with Eelink to deploy smart tracking and telematics solutions at scale. Eelink’s vehicle GPS trackers (such as the TK series) are built not only to locate vehicles, but also to interface with onboard systems for richer telemetry. An example is the Eelink GOT10, a plug-and-play OBD-II tracker that, when inserted into a vehicle’s diagnostic port, can read data like vehicle speed, engine RPM, coolant temperature, fuel level, and more. A city delivery fleet partnered with Eelink to equip 500 vans with these OBD telematics devices, enabling them to monitor driver behavior and vehicle health remotely. The result was a significant improvement in safety (through alerts on speeding or harsh braking) and reduced maintenance costs by catching engine issues early via the reported OBD fault codes.

For larger commercial trucks, Eelink offers hardwired trackers that integrate with the vehicle’s CAN bus and ignition system. One commercial-grade tracker features an LTE Cat-1 module optimized for IoT, plus a relay interface to control the vehicle remotely. A logistics company deployed this device across its tanker truck fleet. The tracker not only uploads location and mileage data for route analytics, but also serves as a remote immobilizer – if a truck is stolen or misused, the operations center can send a command to cut off its ignition/fuel supply safely once the vehicle comes to a stop. Additionally, the tracker’s built-in accelerometer and logic can enforce driver policy; for example, it was configured to trigger a fuel cutoff if persistent speeding is detected, acting as an automated deterrent against dangerous driving. This kind of active telematics control is a game-changer for fleet safety and asset security.

Furthermore, Eelink’s devices support advanced fleet management use cases like Hours-of-Service compliance, predictive maintenance, and route optimization. By streaming engine hours, idle time, and diagnostic info to the fleet’s management platform, the system can log driver working hours automatically (ensuring compliance with regulations like the U.S. DOT HOS rule) and predict when each truck needs service. One Eelink partner integrated these data streams with machine learning models to schedule maintenance only when needed, reducing unplanned breakdowns by 40%. Real-time GPS data from the trackers also feeds route optimization software – if traffic or weather conditions change, managers can redirect drivers dynamically, improving fuel efficiency and delivery times. In sum, by partnering with Eelink, fleet operators are transforming raw vehicle data into actionable insights and control, leading to safer, more efficient, and more profitable operations.

3. Industrial & Remote Asset Monitoring – Rugged Solutions in Action:

Beyond transportation, Eelink collaborates with industrial enterprises to monitor and manage remote assets such as heavy equipment, generators, and containers in the field. These scenarios often involve challenging environments – think of mining sites, offshore platforms, or rural construction projects – where equipment is valuable and conditions are harsh. Eelink’s ultra-rugged asset trackers (like the GPT series) are built for this task. For example, the GPT29 Supply Chain Tracker is a battery-powered device with multi-year standby, capable of tracking shipping containers or railcars that may not have external power. An intermodal logistics firm partnered with Eelink to attach GPT29 units to their cargo containers; the trackers use LTE-M/NB-IoT for transmission when network is available, and log sensor data in memory when out of coverage (such as on the high seas), uploading it later when connectivity is restored. This provided the firm with virtually continuous visibility of container location and condition throughout long-haul journeys, something not previously possible without expensive satellite trackers.

In the energy and utilities sector, Eelink devices are monitoring remote infrastructure. One partner, a renewable energy company, affixed Eelink trackers to remote solar farm equipment and backup generators. These devices, equipped with Modbus interface and digital I/O, could hook into the equipment’s controllers to report run-time, fuel levels, and fault alarms over the air. Through Eelink’s platform, the company set up threshold alerts – e.g. if a generator’s fuel falls below 20% or if a vibration sensor indicates the generator has switched on, managers get an instant notification. The devices’ long battery life (some with 3+ year standby on a single charge) meant even off-grid assets could be tracked without frequent maintenance. In one case, an alert from an Eelink tracker helped detect a critical oil pump failure at a remote site, allowing technicians to intervene before catastrophic damage occurred.

Industrial clients also leverage Eelink’s environmental sensors for compliance and safety. For instance, a food processing plant uses Eelink temperature-humidity loggers in its storage facilities to ensure conditions stay within safe ranges; the loggers send data via a central Eelink gateway to the cloud. If any sensor goes out of range, the system alarms, preventing product spoilage. All these examples underscore Eelink’s ability to deliver reliable, adaptable hardware for tough industrial jobs. The combination of rugged design, low-power operation, and multi-interface connectivity enables partners to keep tabs on assets that were previously “off the grid.” The payoff is improved uptime, better safety, and data-driven decision making in industries where margins and risks are constantly balanced.

Conclusion: Empowering IoT Partnerships with Value and Vision

Eelink’s core strengths – from customized hardware design and dual manufacturing capacity to full-spectrum connectivity and unwavering reliability – position it as an ideal partner for IoT-driven businesses. The company’s collaborative ethos and robust support ensure that partners not only get cutting-edge devices, but also the backing to deploy them successfully at scale. In a field often characterized by hype, Eelink brings tangible engineering substance: ultra-low power algorithms that extend device life, seamless OTA updates that future-proof deployments, and a proven track record with some of the world’s largest IoT projects.

By focusing on value, innovation, and partner readiness, Eelink helps B2B customers transform their operations with IoT. Whether it’s achieving real-time supply chain visibility, optimizing fleet performance, or safeguarding remote assets, Eelink’s ecosystem delivers results that speak to both technical excellence and strategic insight. For decision-makers seeking to leverage IoT hardware as a competitive advantage, the message is clear – choosing a partner like Eelink means gaining a flexible ally committed to engineering success. In an industry where devices are the foundation of digital transformation, Eelink provides the reliability and customization that turn ambitious IoT visions into reality.

By embracing partnership and innovation at its core, Eelink continues to set itself apart as a leader in IoT hardware – empowering businesses worldwide to build smarter, more connected operations.